- 12/06/2024in 2024

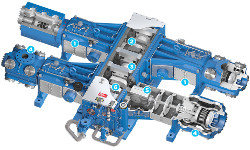

Hydrogen Diesel ICE Prime Mover

... - 09/05/2024in 2022

Bomaderry Manildra Connection

...

"Kallyas Cargo is exactly what our business has been lacking. I would like to personally thank you for your outstanding services."

"I love your system. Definitely worth the investment. I don't know what else to say."

WASCO AUSTRALIA REPRESENTS WASCO ENERGY GROUP IN AUSTRALIA AND OFFERS EPC AND O&M SERVICES IN THE UPSTREAM OIL AND GAS SECTOR.

We are committed to excel in the application of pipe coatings by providing best-in-class solutions and services that meets customer satisfaction through the effective management and implementation of our ISO 9001:2015 accredited quality management system. This is in line with the group strategic objective of developing our brand to be internationally recognized, associated with value, reliability and becoming and employer of choice.

Our quality policy is driven by high level of commitment to quality for the best interest of our stakeholders.

We shall achieve these objectives by:

We practice internationally recognized health, safety and environment (HSE) standards at each of our operations around the world. We are fully committed to delivering quality products and services while ensuring no harm to people, property and the environment. We take a systematic and structured approach to the management of HSE based on suitable systems. HSE is a core value and an integral part of our business culture.

To meet our objectives, we will:

Wasco being committed to the health, safety and efficiency of its employees, will consider seriously any suspicion of substance abuse related to drugs and alcohol by any employees or contractor in the line of duty.

Wasco is committed in protecting it's/our employees from the adverse health effects of the chemical, physical, biological, psychological, and ergonomic risk factors arising from the workplace, and ensuring our employees are fit to work at all time.

Wasco has the responsibility to conduct our business without any detrimental effects on the environment. We comply with all applicable and prevailing laws and industrial standards on waste management, adopting products, systems, and work practices that minimize or reduce waste generation whilst increasing the potential for reuse and recycling of resources.

Effective waste management especially on coating waste in Wasco Coatings Malaysia Sdn. Bhd. and Wasco Lindung Sdn. Bhd. shall comply with WASCO-HSE-PRO-8.1-23 General Waste Management Procedure to ensure that:-

Our safe pipe handling policy is in place to ensure all employees are aware of their fundamental responsibility to work safely in Wasco. Employee’s awareness of the presence of hazards associated with pipe handling is important in achieving a safe workplace where no one gets harmed and no property gets damaged.

Our personal HSE accountability policy is in place to ensure all employees are aware of their fundamental accountability to work safely in Wasco. Employee’s HSE accountability is important in achieving a safe workplace where no one gets harmed and no property gets damaged.

DAILY ACCOUNTABILITY FOR SAFETY , HEALTH AND ENVIRONMENTAL FRIENDLY:

All Wasco employees, contractors, clients and visitors are responsible to stop work activities that are considered to be an "imminent danger".

"Kallyas Cargo is exactly what our business has been lacking. I would like to personally thank you for your outstanding services."

"I love your system. Definitely worth the investment. I don't know what else to say."

Design

Wasco operates a full service multi-discipline engineering

design office, specifically oriented to provision of fit for

purpose engineering and design as part of EPC services

to its customers.

Wasco also has supply agreements with additional local

based engineers and designers whom it calls on as

required to meet demand. Wasco also has the ability to

extend its resources by reaching into Wasco in

Singapore where a multi-discipline Wasco team also

operates.

Supply

Wasco converts design from documentation to product

delivery by working with supply chain partners, selected

vendors, specialist equipment manufacturers and its own

fabrication workshops. Wasco has strong supply chain

links with it's OEM partners across all materials and

equipment required for oil and gas facilites and pipelines.

Our services range from well site installation to steel

pipeline construction, PE gathering, GRE Pipeline

installation and complete Civil, Mechanical, Piping,

Instrument and Electrical installation at facilities such as

Gas Compression, Water Pumping and Gas Dehydration

facilities, mainline valves, metering and scraper stations

and end of line pressure regulation stations.

Install

Wasco self performs installation and testing of the

products and facilities it designs and supplies. Wasco can

provide installation services as head contractor or as a

sub-contract service provider.

Parts

Wasco has a total of 40 field service operators based in

Singapore, Australia, Indonesia and the UAE. This team

provides Wasco clients with reliable post-delivery asset

support and maintenance in addition to commissioning

support and operator training. All centres stock the

necessary spares and consumables for OEM equipment

packaged by Wasco.

Service

Wasco has genuine OEM trained field service technicians

based in Australia,Singapore, Indonesia and the UAE.

This team provides Wasco clients with reliable

post-delivery asset support and maintenance in addition

to commissioning support and operator training. All

centres stock the necessary spares and consumables for

OEM equipment packaged by Wasco.

Wasco is available to answer questions and provide

guidance and advice to owners, operators and engineers

who require assistance in trouble shooting or application

engineering for gas compression.

Support

Wasco is available to answer questions and provide

guidance and advice to owners, operators and

engineers who require assistance in troubleshooting

or application engineering for gas compression OEM.